An Unbiased View of Sandblasting And Powder Coating

Wiki Article

The Best Strategy To Use For Sandblasting And Painting

Table of Contents8 Easy Facts About Sandblasting Machine DescribedHow Sandblasting At Home can Save You Time, Stress, and Money.Some Known Questions About Sandblasting And Painting.About Sandblasting And PaintingUnknown Facts About Sandblasting MachineThe smart Trick of Sandblasting And Powder Coating That Nobody is Talking About

Known as unpleasant blasting, sandblasting is a surface finishing procedure that entails the use of a powered machine usually an air compressor as well as a sandblasting device to spray rough bits under high pressure against a surface area. It's called "sandblasting" because it blasts the surface with fragments of sand.In this message, you'll learn even more about this surface finishing procedure and how it's carried out. Sandblasting leverages the rough residential or commercial properties of sand to create smoother surfaces with fewer physical flaws and problems. It's obvious that sand is harsh and abrasive. Due to these residential or commercial properties, it has the ability to use away at excess or undesirable product on a surface area.

When rubbed against a surface area, the sand gets rid of some of the top-layer product, therefore developing a smoother structure. Sandblasting functions the exact same means other than it entails the use of highly pressurized sand.

The Facts About Sandblasting And Powder Coating Uncovered

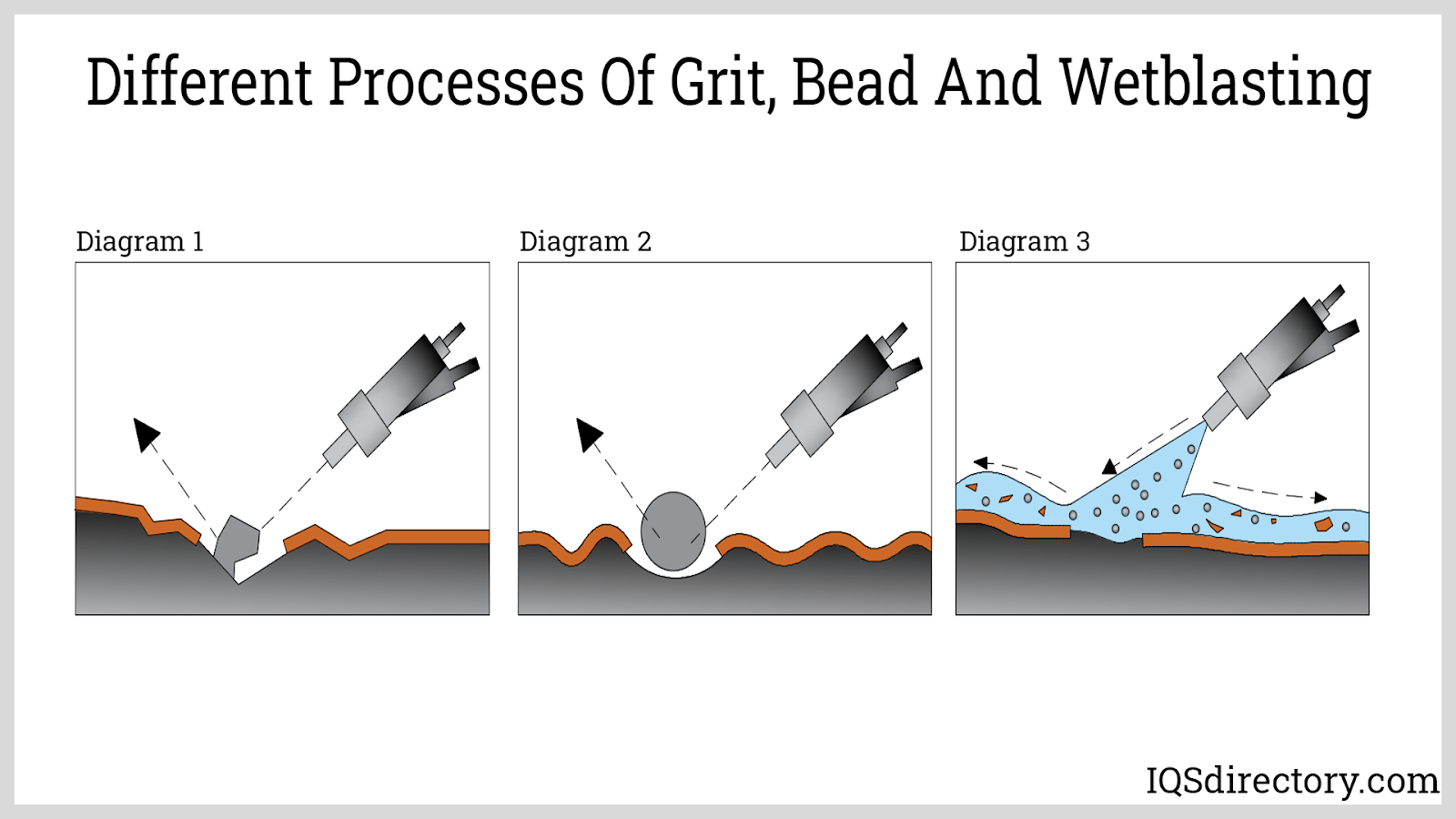

The procedure gets rid of a few of the excess material on the concrete, which subsequently makes it smoother. Sandblasting is simply one of numerous blasting-type surface area completing processes. There's also shot blowing up, which is a lot more effective at smoothing otherwise harsh and stiff surface areas - sandblasting alternatives. What's the distinction in between sandblasting as well as shot blasting specifically? With sandblasting, sand is driven versus a surface.

The rounds or grains are frequently constructed from stainless steel, copper, light weight aluminum or zinc. Regardless, every one of these steels are tougher than sand, making shot blasting even much more effective than its sandblasting equivalent. No tags for this message.

Fascination About Sandblasting And Painting Near Me

Sandblasting is a wonderful method to eliminate rust or paint from a product. By utilizing an abrasive medium and also pressurized air, a sandblaster quickly cleanses a surface as well as leaves it fresh. Prior to beginning, you require to make sure you get the right unpleasant product and know just how to securely make use of a blaster.

Boron carbide is a popular product for nozzles because it resists rough wear well. Wet unpleasant blasting uses water as the fluid moving the abrasives. The benefits are that the water catches the dirt generated, and oils the surface. The water supports the influence on the surface, reducing the removal of audio material.

3 Simple Techniques For Sandblasting Machine

Process speeds are normally not as quick as standard dry rough blowing up when using the equivalent size and also kind of media, partially due to the fact that the existence of water between the media and also the substratum being processed creates a lubricating pillow that can secure both the surface and the media, decreasing break down prices.Wet blowing up of mild steel will certainly lead to instant or 'flash' corrosion of the blasted steel substratum because of the existence of their website water. The absence of surface recontamination additionally enables the usage of solitary tools for several blowing up operationse. g., stainless steel as well as light steel things can be processed in the very same devices with the same media without issues.

In this procedure pressurized air is included in the water in the nozzle generating Learn More Here a high speed haze, called "vapor". This procedure is also milder than damp blasting, allowing mating surfaces to be cleaned while retaining their capacity to mate. Grain blowing up paint from a concrete aesthetic. Blending particles with water considerably decreases dust.

Little Known Facts About Sandblasting.

It is utilized to clean calcium deposits from swimming pool floor tiles or any other surface areas, eliminate ingrained fungi, and brighten cement color. It is additionally used in auto body work to eliminate paint. In getting rid of paint for auto body job, bead blasting is favored over sand blasting, as sand blowing up tends to produce a higher surface area account than bead blasting.

Specialized wheel blast equipments thrust plastic abrasive in a cryogenic chamber, and also is usually used for deflashing plastic and rubber components. The dimension of the wheel blast maker, and also the number and power of the wheels visit their website differ significantly relying on the components to be blasted along with on the anticipated result and also performance. sandblasting alternatives.

Indicators on Sandblasting Aluminum You Should Know

Either the nozzle or component can be relocated in automatic operation. Automated blasting is frequently simply an action in a larger automated treatment, usually involving other surface area therapies such as preparation as well as finish applications.Tool made use of for including sand to the compressed air (top of which is a filter for including the sand) Mobile completely dry unpleasant blast systems are usually powered by a diesel air compressor. The air compressor gives a big volume of high stress air to a single or numerous "blast pots".

Report this wiki page